Contact us for more information!

A REVOLUTION IN INNOVATION

It’s no secret that there is a growing demand for more powerful outboard motors. These new outboard motors have fueled a demand for larger boat designs that previously may have been powered by stern drive or other inboard power. As more powerful outboards are introduced, the boats get bigger and as the boats get bigger, outboards are getting more muscular.

A FORCE TO MATCH THE POWER OF NATURE AND THE SEA

Suzuki has embarked on a major engineering expedition to build the Ultimate 4-Stoke Outboard Motor. In developing the new DF350A, Suzuki Engineers started with a clean sheet of paper and considered many factors for this design. Making more horsepower can be accomplished in many ways. The engine design can include larger displacement and adding turbo chargers or superchargers. However, larger displacement engines typically burn more fuel and increase the overall weight. While adding complex mechanical components can create reliability concerns. Once you have all of that horsepower, now the challenge is getting it to hook up or grab traction in the water. Suzuki Engineers labored through years of trial and success with computer simulations and on water testing to significantly improve the way an outboard motor converts engine power to underwater thrust. Join us as Suzuki introduces the next milestone in our history…..The 350 horsepower DF350A….Suzuki’s Ultimate 4-Stroke Outboard Motor.

Specifications

- Transom Height – X: 25 – XX: 30 (in)

- Starting System – Electric – Suzuki Start System

- Weight – X: 726 – XX: 745 (lbs)

- Engine Type – DOHC 24-Valve

- Fuel Delivery System – Multi Point Sequential Electronic Fuel Dual Injection with Lean Burn and Oxygen Sensor

- Piston Displacement – 267.9 (4,390) (cc)

- Bore x Stroke – 98 (3.74) x 97 (3.82)

- Max Horse Power – 350HP

- Operating Range – 5300 – 6300 (RPM)

- Steering – Remote

- Oil Pan Capacity – 8.5 (8.0) (L)

- Ignition System – Solid State Direct Ignition

- Trim Position – Power Trim and Tilt

- Gear Ratio – 2.29:1

- Standard Propeller – Contra-Rotating Propellers *Not Included*

- Propeller Selection – 12″-31.5″

***Available in White and XL: 25″ leg, call for Details

COMPRESSION RATIO

Our solution to developing 80 horsepower per liter in a V6 350 horsepower engine was to increase the compression ratio to 12.0:1, the highest compression ratio ever for a production outboard engine. In order to make this work without knocking (a typical problem at this ratio), we developed systems to mix cooler air with well-atomized fuel to provide optimal conditions for complete, and controlled combustion.

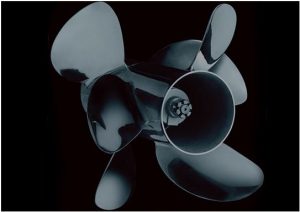

DEVELOPMENT OF SUZUKI’S FIRST CONTRA-ROTATING PROPELLER

Our engineers know that the shape of the lower unit and the design of the propeller have a critical impact on performance. The innovative contra-rotating propeller design provides more grip underwater, and because contra-rotating propellers distribute the engine’s torque evenly over two propellers, the torque per propeller decreases and gear diameter can be reduced. A reduction in gear diameter has allowed the design of a smaller, and far more hydrodynamic gear case.

GEAR CASE DESIGN

At high speeds cavitation can cause significant losses in speed and grip. The New DF300B overcomes this with a highly advanced gear case design. Computational fluid dynamics (CFD) and countless test drives, have resulted in a breakthrough design that not only minimizes resistance but also provides a highly efficient flow of water to the propellers.

PROPELLER BLADE DESIGN

The new three-blade/three-blade propeller set up has been developed that provides incredible acceleration and increased performance. In testing, this configuration recorded the highest speeds, even under heavy load and at high rotation speeds. The propeller blade geometry has also been optimized to work in the configuration resulting in incredible grip and acceleration across the range. An added benefit is exceptional stability, achieved because each propeller rotates in a different direction, balancing the turn.

HIGH REVERSE THRUST

The gear material was changed and heat treatment was added to endure the added thrust and inertial mass from the reverse thrust, which was stronger on a contra-rotating propeller. In addition, the reverse gear was moved above the cavitation plate and the position of the lower engine mounts was modified from parallel to V-shape to fit the reverse gear above the cavitation plate.

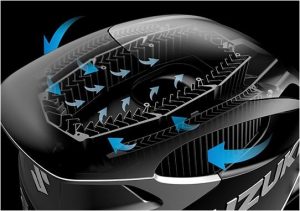

DIRECT INTAKE SYSTEM AND DUAL LOUVER SYSTEM FOR COOL AND DRY AIR

Achieving a flow of cooler, drier air directly into the engine is made possible by the unique combination of the Direct Intake System and the Dual Louver System. This revolutionary approach ensures a direct flow of air whilst eliminating water intake, even in the face of the most severe on-water testing. The Dual Louver System incorporates a double shield of blades, each one designed in a dog-leg shape. This system helps remove water from the air and prevents water to be taken into the cowl. As a result, intake air is free of moisture and kept close to ambient temperature.

DUAL INJECTORS FOR BOTH COOLING AND POWER

Injecting fuel does two things, it atomizes the fuel and, it cools the cylinder to minimize knock. To achieve the power we wanted, we needed to inject 100% of the fuel into the cylinder all at once, at a precise time, and at a precise angle to both cool the cylinder and to allow combustion to take place in the center of the combustion chamber. The new Dual Injector System using two smaller injectors provided the required precision as well as improved atomization , increasing output by 3% without knocking.

ATTENTION TO DETAIL – TECHNOLOGICALLY ADVANCED PISTONS

With the higher compression ratio, more is being asked of the piston than ever before. Not only does the surface have to withstand greater forces, but the connecting rod and hardware do too. To help the piston withstand the added lateral pressure, the change to shot peening from the standard surface treatment was conducted. Shot peening creates fine dimples on the surface that evenly distribute the pressure created during combustion. We are proud to say that we were able to create a piston worthy of the “ULTIMATE” title.

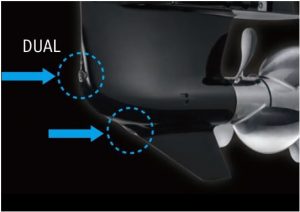

DUAL WATER INLET

Dual water inlet is a technology developed to cool the engine with minimal friction loss, using a combination of a small water pump and dynamic water pressure. Conventional outboards have water inlets on the side of the strut of the gear case. However, at very high speed, the water pressure at the strut surface is reduced, making it difficult to maintain stable water suction. The DF350A has water inlets on the tip of the gear case, which helps with water suction even when there is dynamic pressure caused by the movement of the gear case through the water.

SPC – Suzuki Selective Rotation – BETTER STEERING IN ALL DIRECTIONS

Normally, when using multiple outboards a combination of standard and counter-rotating engines are mounted. The Suzuki Selective Rotation is available on our AP series outboards, eliminates the need for different models, as any model can be easily programmed to run in either direction. The DF350A’s contra-rotating propeller technology takes this process one step further by eliminating steering torque and maximizing true and straight propulsion forces.